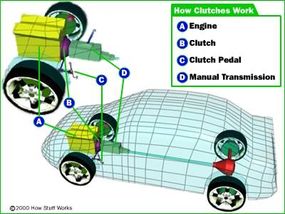

If you drive a manual transmission car, you may be surprised to find out that it has more than one clutch. And it turns out that folks with automatic transmission cars have clutches, too. In fact, there are clutches in many things you probably see or use every day: Many cordless drills have a clutch, chain saws have a centrifugal clutch and even some yo-yos have a clutch.

In this article, you’ll learn why you need a clutch, how the clutch in your car works and find out some interesting, and perhaps surprising, places where clutches can be found.

Clutches are useful in devices that have two rotating shafts, including cars. One of the shafts is typically driven by a motor or pulley, and the other shaft drives another device. The clutch connects the two shafts so that they can either be locked together and spin at the same speed, or be decoupled and spin at different speeds.

In a car, you need a clutch because the engine spins all the time, but the car’s wheels do not. In order for a car to stop without killing the engine, the wheels need to be disconnected from the engine somehow. The clutch allows us to smoothly engage a spinning engine to a transmission that is not spinning by controlling the slippage between them.

To understand how a clutch works, it helps to know a little bit about friction, which is a measure of how hard it is to slide one object over another. Friction is caused by the peaks and valleys that are part of every surface — even very smooth surfaces still have microscopic peaks and valleys. The larger these peaks and valleys are, the harder it is to slide the object.

A clutch works because of friction between a clutch plate and a flywheel. We’ll look at how these parts work together in the next section.

Fly Wheels, Clutch Plates and Friction

In a car’s clutch, a flywheel connects to the engine, and a clutch plate connects to the transmission.

Exploded View of a Clutch

When your foot is off the clutch pedal in a manual car, springs push the pressure plate against the clutch disc, which in turn presses against the flywheel. This locks the engine to the transmission input shaft, causing them to spin at the same speed.

The amount of force the clutch can hold depends on the friction between the clutch plate and the flywheel, and how much force the spring puts on the pressure plate. The friction force in the clutch works just like the blocks described in the friction section of How Brakes Work, except that the spring presses on the clutch plate instead of weight pressing the block into the ground.

How a Clutch Engages and Releases

When the clutch pedal is pressed, a cable or hydraulic piston pushes on the release fork. This in turn presses the release bearing, which disengages the engine from the transmission during gear shifts, against the middle of the diaphragm spring. As the middle of the diaphragm spring is pushed in, a series of pins near the outside of the spring causes the spring to pull the pressure plate away from the clutch disc. This releases the clutch from the spinning engine.

Note the springs in the clutch plate. These springs help to isolate the transmission from the shock of the clutch engaging.

This design usually works pretty well, but it does have a few drawbacks. We’ll look at common clutch problems and other uses for clutches in the following sections.

Common Problems

From the 1950s to the 1970s, you could count on getting between 50,000 and 70,000 miles (80,467 and 113,000 kilometers) from your car’s clutch. Clutches can now last for more than 80,000 miles (128,747 kilometers) if you use them gently and maintain them well. If not cared for, clutches can start to break down at 35,000 miles (56,327 kilometers). Trucks that are consistently overloaded or that frequently tow heavy loads can also have problems with relatively new clutches.

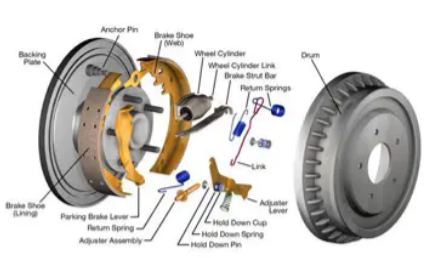

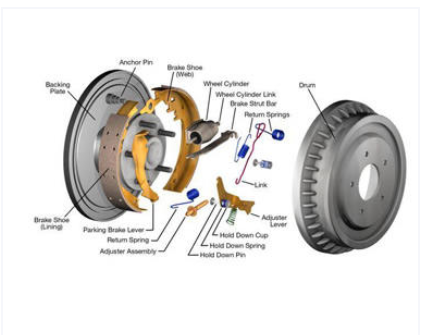

The most common problem with clutches is that the friction material on the disc wears out. The friction material on a clutch disc is very similar to the friction material on the pads of a disc brake or the shoes of a drum brake— after a while, it wears away. When most or all of the friction material is gone, the clutch will start to slip, and eventually it won’t transmit any power from the engine to the wheels.

The clutch only wears while the clutch disc and the flywheel are spinning at different speeds. When they are locked together, the friction material is held tightly against the flywheel, and they spin in sync. It’s only when the clutch disc is slipping against the flywheel that wearing occurs. So, if you are the type of driver who slips the clutch a lot, you’ll wear out your clutch a lot faster.

Sometimes the problem is not with slipping, but with sticking. If your clutch won’t release properly, it will continue to turn the input shaft. This can cause grinding, or completely prevent your car from going into gear. Some common reasons a clutch may stick are:

- Broken or stretched clutch cable: The cable needs the right amount of tension to push and pull effectively.

- Leaky or defective slave and/or master clutch cylinders: Leaks keep the cylinders from building the necessary amount of pressure.

- Air in the hydraulic line: Air affects the hydraulics by taking up space the fluid needs to build pressure.

- Misadjusted linkage: When your foot hits the pedal, the linkage transmits the wrong amount of force.

- Mismatched clutch components: Not all aftermarket parts work with your clutch.

A “hard” clutch is also a common problem. All clutches require some amount of force to depress fully. If you have to press hard on the pedal, there may be something wrong. Sticking or binding in the pedal linkage, cable, cross shaft, or pivot ball are common causes. Sometimes a blockage or worn seals in the hydraulic system can also cause a hard clutch.

Another problem associated with clutches is a worn clutch release bearing, sometimes called a throw-out bearing. This bearing applies force to the fingers of the spinning pressure plate to release the clutch. If you hear a rumbling sound when the clutch engages, you might have a problem with the throw-out.

In the next section, we’ll examine some different types of clutches and how they are used.

Types of Clutches

There are many other types of clutches in your car and in your garage.

An automatic transmission contains several clutches. These clutches engage and disengage various sets of planetary gears, which are made of a central drive gear surrounded by gears that orbit it. Each clutch in an automatic transmission is put into motion using pressurized hydraulic fluid. When the pressure drops, springs cause the clutch to release. Evenly spaced ridges, called splines, line the inside and outside of the clutch to lock into the gears and the clutch housing. You can read more about these clutches in How Automatic Transmissions Work.

An air conditioning compressor in a car has an electromagnetic clutch. This allows the compressor to shut off even while the engine is running. When current flows through a magnetic coil in the clutch, the clutch engages. As soon as the current stops, such as when you turn off your air conditioning, the clutch disengages.

Most cars that have an engine-driven cooling fan have a thermostatically controlled viscous clutch— the temperature of the fluid actually drives the clutch. This clutch is positioned at the hub of the fan, in the airflow coming through the radiator. The fluid in the clutch gets thicker as it heats up, causing the fan to spin faster to catch up with the engine rotation. When the car is cold, the fluid in the clutch remains cold and the fan spins slowly, allowing the engine to quickly warm up to its proper operating temperature.

Many cars have limited slip differentials or viscous couplings, both of which use clutches to help increase traction. When your car turns, one wheel spins faster than the other, which makes the car hard to handle. The slip differential makes up for that with the help of its clutch. When one wheel spins faster than the others, the clutch engages to slow it down and match the other three. Driving over puddles of water or patches of ice can also spin your wheels.

Gas-powered chain saws and weed eaters have centrifugal clutches, so that the chains or strings can stop spinning without you having to turn off the engine. These clutches work automatically through the use of centrifugal force. The input is connected to the engine crankshaft. The output can drive a chain, belt or shaft. As the rotations per minute increase, weighted arms swing out and force the clutch to engage. Centrifugal clutches are also often found in lawn mowers, go-karts, mopeds and mini-bikes. Even some yo-yos are manufactured with centrifugal clutches.

Clutches are valuable and necessary to a number of applications. For more information on clutches and related topics, check out the links below.